Select products you want to compare

Partially cover the range: Show products that work over part of the specified range.

:

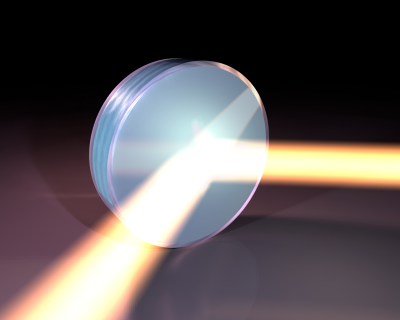

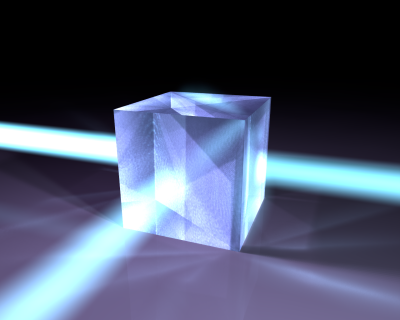

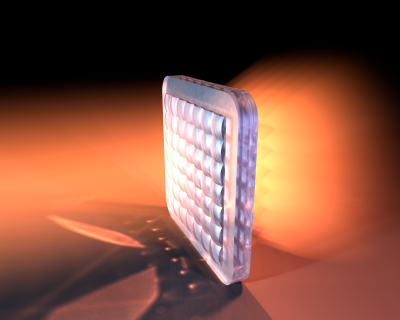

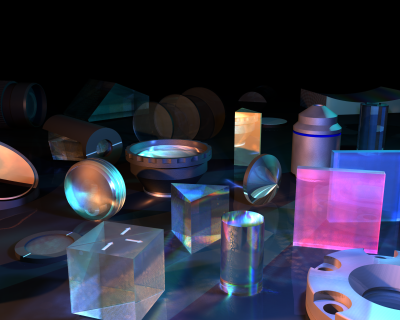

Optical substrates are designed to transmit across a specified wavelength range with specific dispersion and thermal expansion characteristics.

[Learn More] Thickness indicates the distance between two surfaces. Larger thickness allows for greater heat dissipation and higher resistance to stress in machining, blocking, and handling, however it increases weight and dispersion.

[Learn More] Surface quality measures surface imperfections and is expressed by two numbers separated by a hyphen (scratch-dig). The first number refers to scratches and the second to digs or pits, where lower numbers indicate higher quality.

[Learn More] The clear aperture is the pupil of the system that preserves all specifications defined by the manufacturer. It is always smaller than the diameter of the optic.

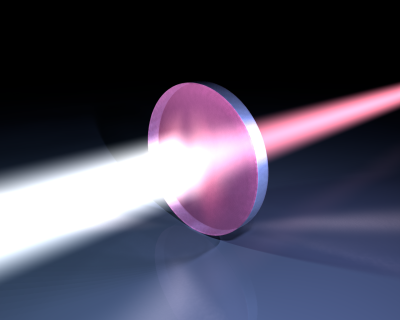

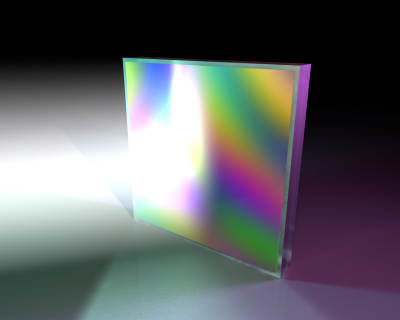

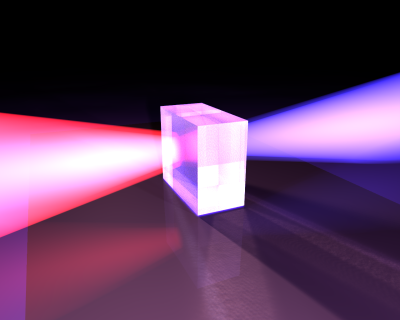

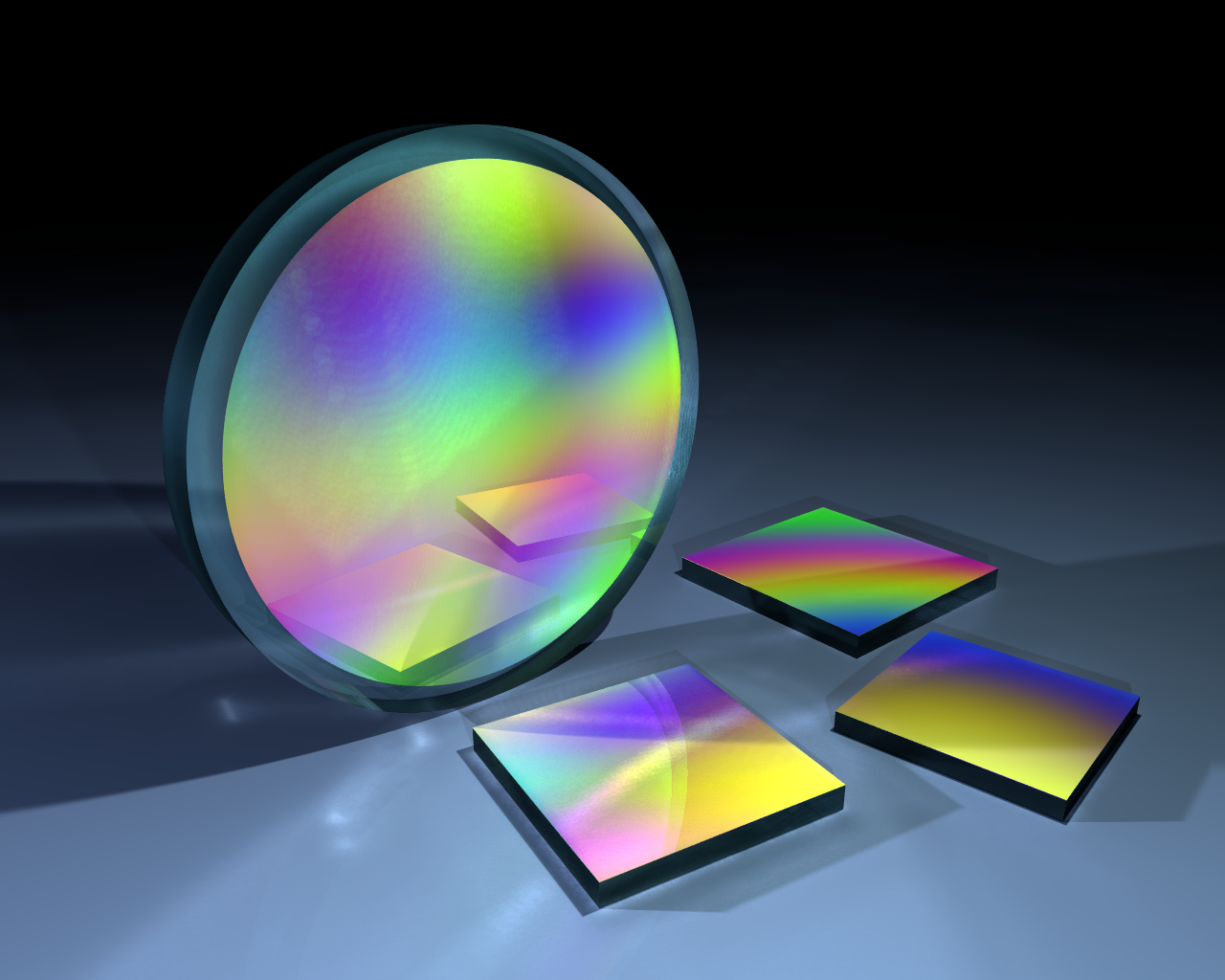

[Learn More] Coatings are used to alter the reflective properties of a surface. They can be used to increase transmission (AR Coatings), increase reflection (HR Coatings) or selectively transmit or reflect certain wavelengths.

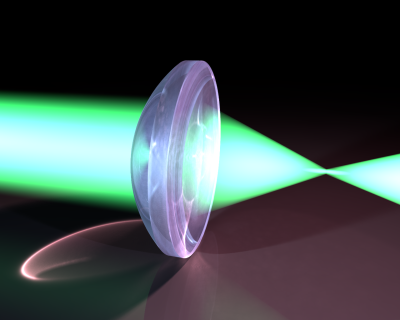

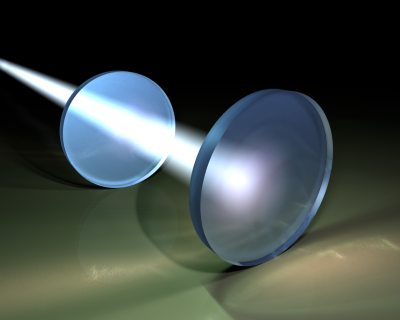

[Learn More] The focal length measures the strength of an optical system to converge (focus) or diverge light. It is related to the radius of curvature and inversely proportional to the optical power.

[Learn More] Surface Irregularity, Surface Flatness or Surface Figure is the maximum deviation from a fully flat face along the same lateral dimensions specified in fraction of reference wavelength.

[Learn More] The pulsed damage threshold indicates the fluence that an optic can withstand without being damaged by a pulsed laser. F (J/cm2) = Ep (J) / A (cm2).

[Learn More] Center thickness is the material thickness of the component measured at its center.

[Learn More] Fiber optic connectors align and connect two or more fibers together to provide a means for attaching to, or decoupling from, a transmitter, receiver, or any other fiber optic component.

[Learn More] Edge thickness is the material thickness of an optical component measured at the edge.

[Learn More] Quantifies the range of angles over which an optical system can accept or emit light. In a single lens, it is proportional to the optics diameter and inversely proportional to the focal length.

[Learn More] Thickness tolerance indicates how much variation around the specified thickness is expected given the manufacturing process.

[Learn More] The f/# is the ratio of the focal length, (f), of the lens to the effective aperture diameter. The larger the f-number, the smaller the aperture, and the lower the light throughput.

[Learn More] It is the free space between the object plane (sample) and the first surface of the first element from the object in a complex lens (optical assembly) or the front edge of a single lens.

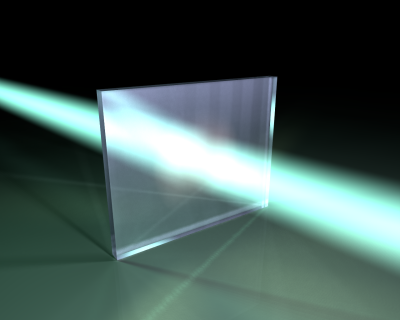

[Learn More] Beam deviation indicates the angle between the incident and the transmitted or reflected beam after traversing the optical component.

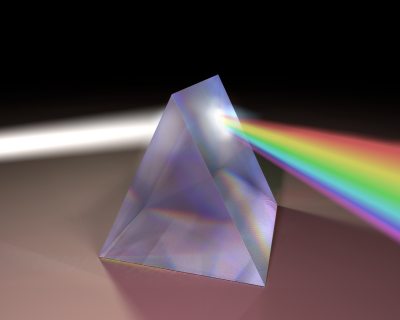

[Learn More] Optical density measures how well a component blocks light passing through it. A high optical density indicates very low transmission. OD is measured on a log scale.

[Learn More] Angle of incidence gives the angle from normal incidence for which the optic can be used.

[Learn More] The interface refers to the protocol and hardware for transferring the image data from the camera sensor to the external device or system for processing, storage or display.

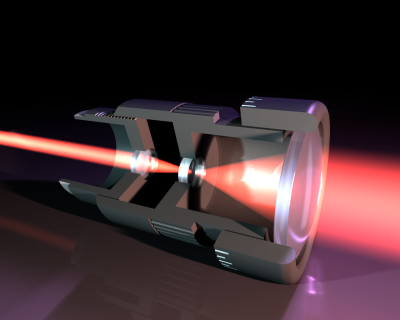

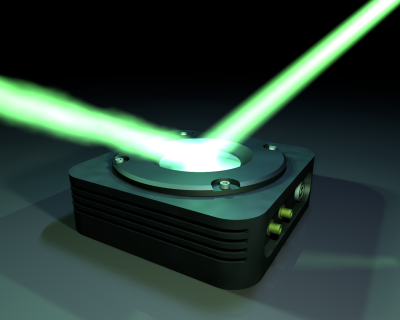

[Learn More] Cooled mounts are used in laser systems to control and stabilize the temperature. By actively dissipating heat away from these components, cooled mounts prevent excessive temperatures and consequent damage.

[Learn More] Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy

Copy