Menu

- Home

- Login

- Products

- Optics

- Lasers & Light Sources

- Optomechanics

- Fiber Optics

- Detection Devices

- Electro-Optics & Electronics

- Machines

- Imaging & Microscopy

- Design Software

- Raw materials

- Photonic Integrated Circuits

- Custom Suppliers

- Company

- Resources

- OpticsLasers & Light SourcesOptomechanicsFiber OpticsDetection DevicesElectro-Optics & ElectronicsMachinesImaging & MicroscopyDesign SoftwareRaw materialsPhotonic Integrated Circuits

- Custom Suppliers

Notifications

Mark all as read

Zeeko has joined our supplier lineup. Check out their catalog products.

2d

Introducing high-E Photonics! Explore their products on our website.

2d

Welcome aboard Piezolution! Find their catalog products now featured on MEETOPTICS.

1w

New manufacturer announcement: Get to know SMART Photonics and their latest product offerings.

1w

Introducing LIGENTEC! Explore their photonic foundry service on our website.

1w

LioniX International has joined our supplier lineup. Check out their customized microsystem solutions.

1w

New manufacturer announcement: Get to know Polariton Technologies and their latest custom PIC offerings.

1w

Welcome aboard ficonTEC! Find their catalog products and solutions now featured on MEETOPTICS.

1w

We have a new categorization for Photonic Integrated Circuits. Find all the products from trusted suppliers.

2w

Introducing Yalosys Ltd! Explore their laser microprocessing solutions on our website.

2w

Epiphany has joined our supplier lineup. Check out their photonic design solutions.

2w

New manufacturer announcement: Get to know Light Trace Photonics and their latest product offerings.

2w

- Your cart is empty. Please add some items.

LASER WELD - LASER WELD

LASER WELD

Product Line

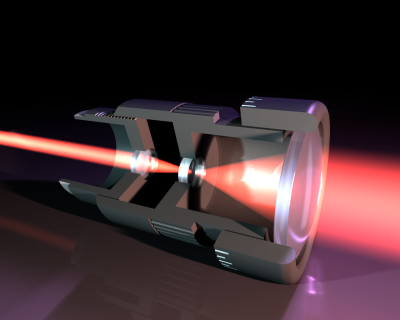

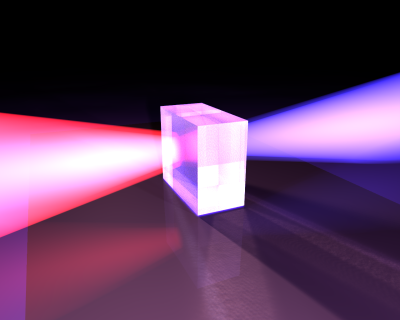

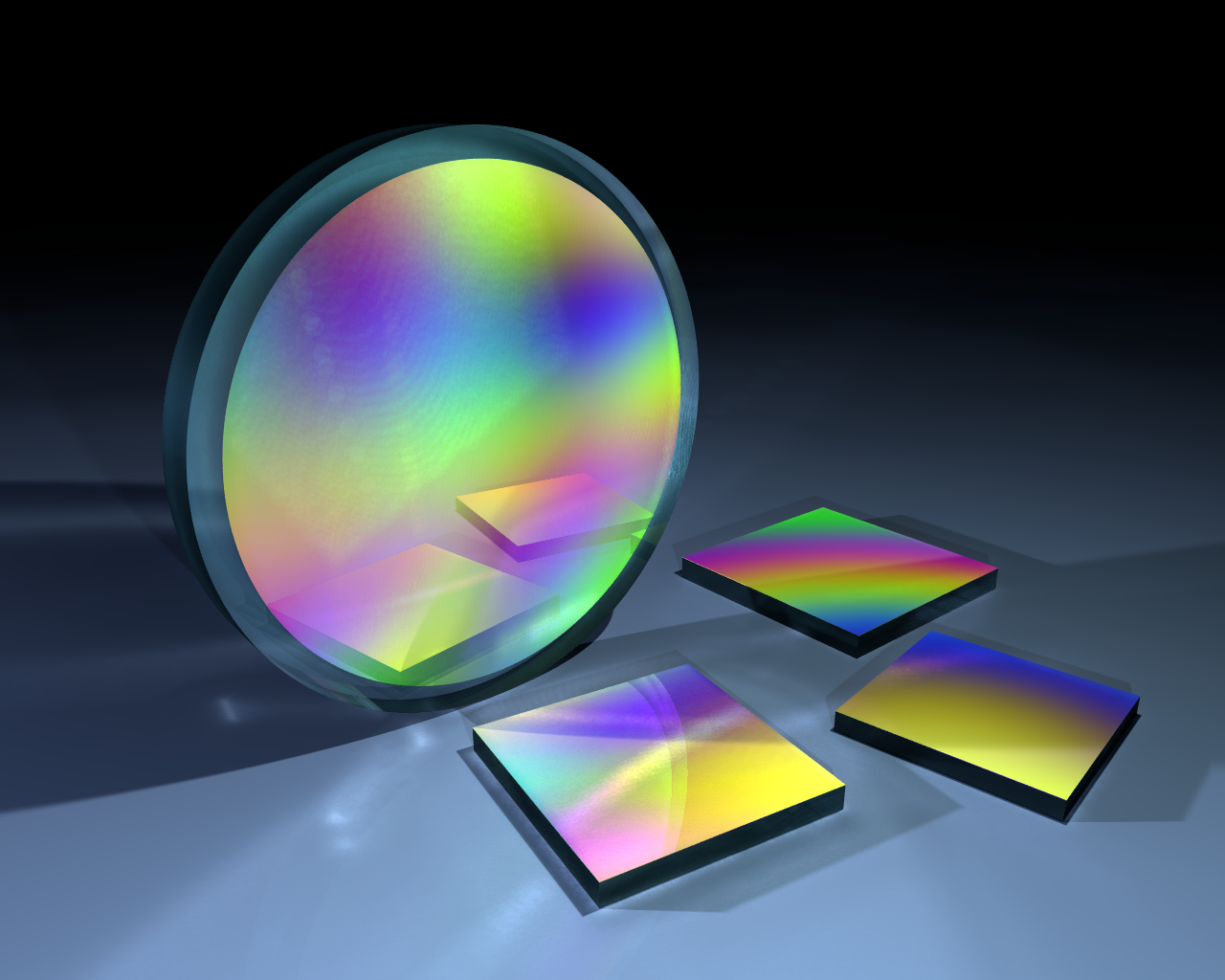

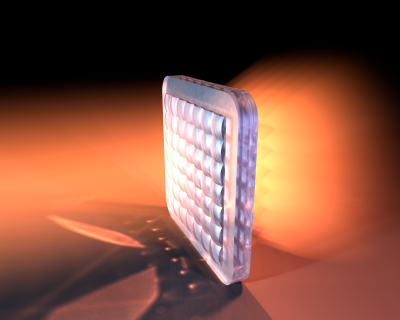

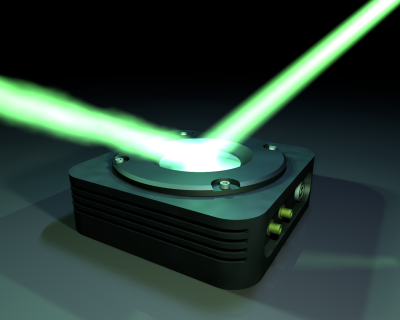

LASER WELD systems are advanced, fully automated microwelding production cells designed for the photonics industry. These systems excel in optical assembly and coupling light out of photonic device packaging, such as butterfly, TO, and custom formats. They utilize either ferruled optical components or single/multi-fiber coaxial assemblies. The systems feature a vertical dual-stage layout, with each stage equipped with high-precision multi-axis movement. The 2-beam configuration allows for direct fiber-to-chip coupling and confocal optical train assembly of miniature components within standard package formats. Meanwhile, the 3-beam configuration offers 45° or 90° beam out-of-plane incidence, suitable for fillet or butt/lap-style welding of coaxial components. The welding process accommodates both passive and actively driven components and can include an optional inert gas feed to enhance weld quality. Post-weld characterization and testing ensure performance and yield monitoring, with a 'post-weld shift' correction capability for addressing 'out-of-spec' results.

Product Specifications

The LASER WELD is an automated microwelding station designed for photonics, offering a 2 or 3-beam vertical configuration with a fiber-coupled Nd:YAG laser. It features configurable high-precision multi-axis motion systems, pick-&-place device handling, and temperature-controlled chuck options. The system supports manual loading and offers flexible feed options. Machine vision capabilities include system referencing and observation camera options, while software features provide powerful process programming and Windows 10 PC compatibility. The station ensures cleanroom compliance with ISO 6 standards and is built on a rugged steel base. It is available either with dimensions of 800 x 1200 x 2000 mm and a weight of 1300 kg or 1200 x 1200 x 2000 mm and a weight of 1800 kg.

- Product Code

- Applications

- Welding

- Construction

- Rugged steel base production cell

- Housing Dimensions

- 800 x 1200 x 2000 mm (LW800)

1200 x 1200 x 2000 mm (LW1200) - Key Features

- Fully Automated 2 or 3-Beam Microwelding Station

Post-Weld Shift Correction Capability

Precise Angular Control for Lower Tooling Stage - Load Options

- Manual loading

- Machine Vision

- System referencing and observation camera options

Device and I/O port referencing - Minimum Connections

- 120 VAC (or country specific)

Air/vacuum

Process gas on request

100 Mbit/s network - Motion System

- Configurable high-precision multi-axis upper and lower tooling stages 3-axis beam delivery control

- Options

- Custom Device Package Tooling Available

- Software Features

- Flexible and powerful process programming, Windows 10 PC

- Supplier Location

- Germany

Technical Documents

Search and compare Material Processing Systems from trusted suppliers

Start Search UPC Campus Nord, Espai Emprèn

C. Jordi Girona 1-3, C3 S1

08034, Barcelona

info@meetoptics.com